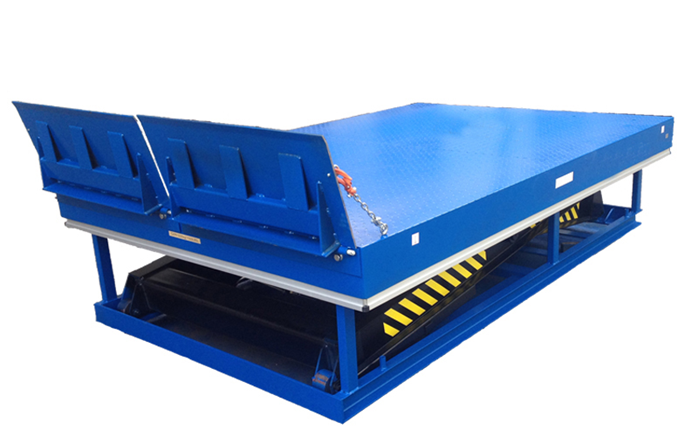

I-Pit Scissor Lift Table

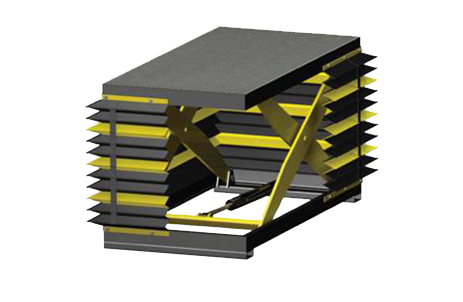

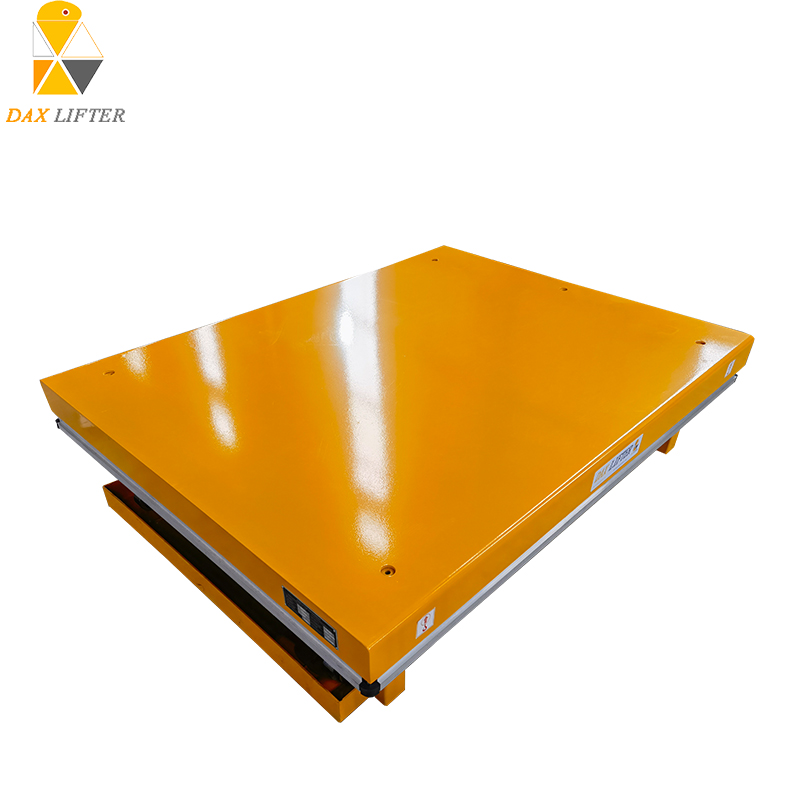

Ithebula le-pit scissor lift lisetshenziselwa ukudlulisa izimpahla zisuka kwesinye isendlalelo sokusebenza ziye kwesinye. Umthamo wokuthwala umthwalo, usayizi wesikhulumi, nokuphakama kokuphakamisa kungakhethwa ngokuya ngezidingo zangempela phakathi nomsebenzi. Uma okokusebenza kufakwe emgodini, ngeke kube yisithiyo uma impahla ingasebenzi. Sinezinye ezimbili ezifanayoI-Low Scissor Lift Table. Uma udinga elinye itafula lokuphakamisa elinemisebenzi ehlukene, singakunikeza futhi.

Uma kunemishini yokuphakamisa oyidingayo, ungangabazi ukusithumelela uphenyo ukuze uthole ulwazi olwengeziwe lomkhiqizo!

FAQ

IMP: Yebo, kunjalo, sicela usitshele ubude bokuphakamisa, umthamo womthwalo kanye nosayizi weplathifomu.

A: Ngokuvamile, i-MOQ iyisethi engu-1. Imikhiqizo ehlukene ine-MOQ ehlukile, sicela uxhumane nathi.

A: Sesineminyaka eminingi sibambisana nezinkampani zemikhumbi ezichwepheshile, futhi zinganikeza usizo olukhulu lochwepheshe kwezokuthutha kwethu.

IMP: Amatafula ethu okuphakamisa izikele asebenzisa ukukhiqizwa Okujwayelekile okuzonciphisa izindleko eziningi zokukhiqiza. Ngakho intengo yethu izoncintisana kakhulu, okwamanje iqinisekisa ikhwalithi yetafula lethu lokuphakamisa isikele.

Ividiyo

Imininingwane

| Imodeli | Layisha Amandla (KG) | Uqobo lwakhoUbude (MM) | UbukhuluUbude (MM) | Usayizi Wenkundla(MM) L×W | Usayizi Oyisisekelo (MM) L×W | Isikhathi sokuphakamisa (S) | Amandla kagesi (V) | Imoto (kw) | Isisindo sengqikithi (KG) |

| I-DXTL2500 | 2500 | 300 | 1730 | 2610*2010 | 2510*1900 | 40 ~ 45 | Ngokwezifiso | 3.0 | 1700 |

| DXTL5000 | 5000 | 600 | 2300 | 2980*2000 | 2975*1690 | 70~80 | 4.0 | 1750 |

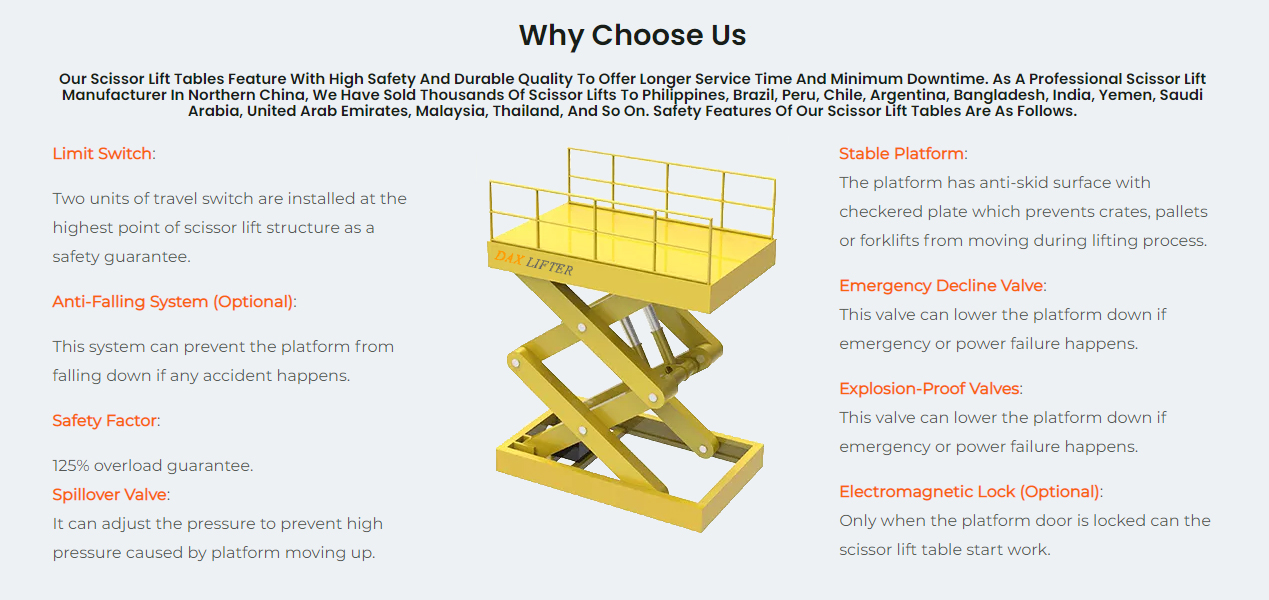

Izinzuzo

Iyunithi yamandla weHydraulic esezingeni eliphezulu:

I-Low Profile Platform isebenzisa iyunithi yamandla e-hydraulic yekhwalithi ephezulu yegama lomkhiqizo, esekela inkundla yokuphakamisa uhlobo lwesikelo ngokusebenza okuhle kokusebenza namandla aqinile.

Ukwelashwa Kwekhwalithi ephezulu:

Ukuze kuqinisekiswe impilo ende yesevisi yezinto zokusebenza, indawo engaphezulu yesikelo sethu esisodwa iphathwe ngokuqhunyiswa kwesibhamu nopende wokubhaka.

Ungathathi isikhala:

Ngenxa yokuthi ingafakwa emgodini, ngeke ithathe indawo futhi ibe isithiyo uma ingasebenzi.

Ifakwe Ivalvu Yokulawula Ukugeleza:

Imishini yokuphakamisa ifakwe i-valve yokulawula ukugeleza, evumela ukuthi isivinini sayo silawulwe ngesikhathi senqubo yokwehla.

I-valve yokulahla izimo eziphuthumayo:

Esimeni esiphuthumayo noma ukwehluleka kwamandla, ingehla ngokushesha ukuze kuqinisekiswe ukuphepha kwempahla kanye nabaqhubi.

Izinhlelo zokusebenza

Icala 1

Elinye lamakhasimende ethu ase-Belgian lithenge itafula lethu lokuphakamisa isikere somgodi ukuze kuthulwe amaphalethi e-warehouse. Ikhasimende lifake izinto zokuphakamisa umgodi emnyango wesitolo. Ngaso sonke isikhathi lapho kulayisha, izinto zokuphakamisa isikelo zingaphakanyiswa ngokuqondile ukuze zilayishe impahla ye-pallet elolini. . Ukuphakama okunjalo kwenza umsebenzi ube lula futhi kuthuthukisa kakhulu ukusebenza kahle komsebenzi. Ikhasimende linolwazi oluhle kakhulu ekusebenziseni imishini yethu yokuphakamisa futhi lanquma ukubuyisela imishini emisha engu-5 ukuze lithuthukise ukusebenza kahle kokulayisha kwempahla.

Icala lesi-2

Ikhasimende lethu lase-Italy lithenge imikhiqizo yethu ukuze ilayishe impahla esikhumulweni semikhumbi. Ikhasimende lifake i-pit lift endaweni yemikhumbi. Lapho ulayisha impahla, iplatifomu yokuphakamisa ingaphakanyiswa ngokuqondile ifinyelele ukuphakama okufanele futhi imithwalo ye-pallet ingalayishwa ethuluzini lokuthutha. Ukusetshenziswa kwemishini yokuphakamisa umgodi kwenza umsebenzi ube lula futhi kuthuthukisa kakhulu ukusebenza kahle komsebenzi. Izinga lemikhiqizo yethu lamukelwe kahle ngamakhasimende, futhi amakhasimende ayaqhubeka nokuthenga imikhiqizo azoyisebenzisa emsebenzini wakhe ukuthuthukisa ukusebenza kahle.

| 1. | Isilawuli kude |

| Umkhawulo phakathi kuka-15m |

| 2. | Foot-step Control |

| 2m ulayini |

| 3. | Amasondo |

| Kudingeka kwenziwe ngendlela oyifisayo(kucatshangelwa umthamo womthwalo kanye nokuphakama kokuphakamisa) |

| 4. | Irola |

| Kudingeka kwenziwe ngendlela oyifisayo (kucatshangelwa ububanzi be-roller negebe) |

| 5. | Ukuphepha Ngezansi |

| Kudingeka kwenziwe ngendlela oyifisayo(kucatshangelwa usayizi weplathifomu nokuphakama kokuphakamisa) |

| 6. | Abaqaphi |

| Kudingeka kwenziwe ngendlela oyifisayo(kucatshangelwa usayizi weplathifomu nobude bezinsimbi zokuqapha) |