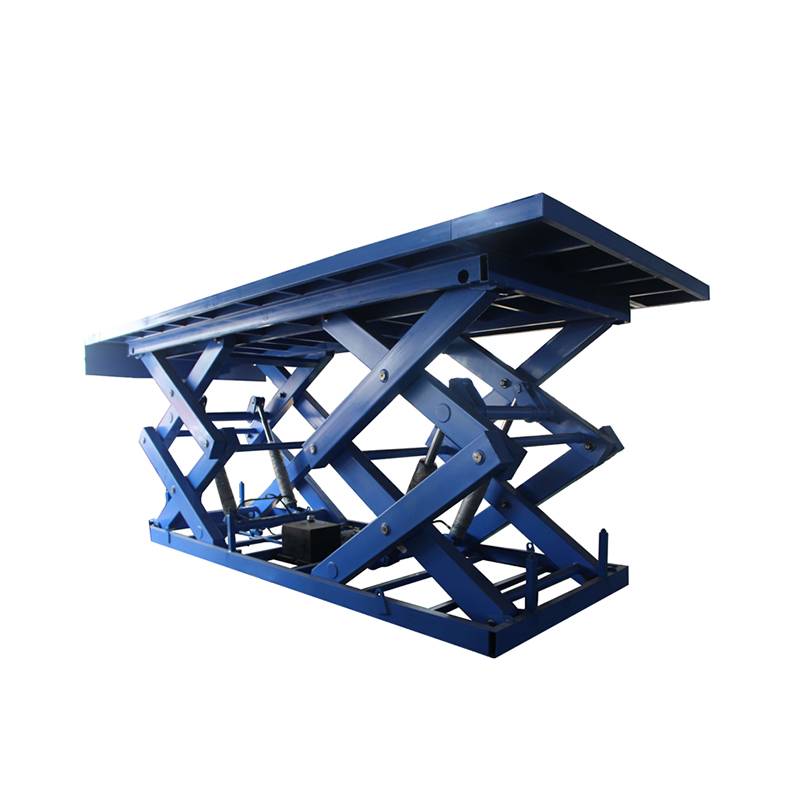

Amathebula Okuphakamisa I-Hydraulic Roller Scissor Angokwezifiso

Lapho wenza ngokwezifiso iplathifomu yokuphakamisa ama-roller, udinga ukunaka lezi zindaba ezibalulekile ezilandelayo:

1. Cacisa izidingo zokusetshenziswa: Okokuqala, kuyadingeka ukucacisa izimo zokusetshenziswa kwesikhulumi, uhlobo, isisindo kanye nosayizi wezimpahla okufanele zithwalwe, kanye nezidingo zokuphakamisa ukuphakama nesivinini. Lezi zidingo zizoba nomthelela ngqo ekwakhiweni kwangokwezifiso kwenkundla nokukhetha kokusebenza.

2. Cabangela ukuphepha: Ukuphepha kungenye yezinto ezicatshangelwayo ezibaluleke kakhulu lapho wenza ngendlela oyifisayo inkundla yokuphakamisa amasondo. Kuyadingeka ukuqinisekisa ukuthi inkundla inemisebenzi yokuphepha efana nokuvikela ukugcwala kakhulu nokuma kwesimo esiphuthumayo, futhi ithobela izindinganiso nemithetho zokuphepha efanele.

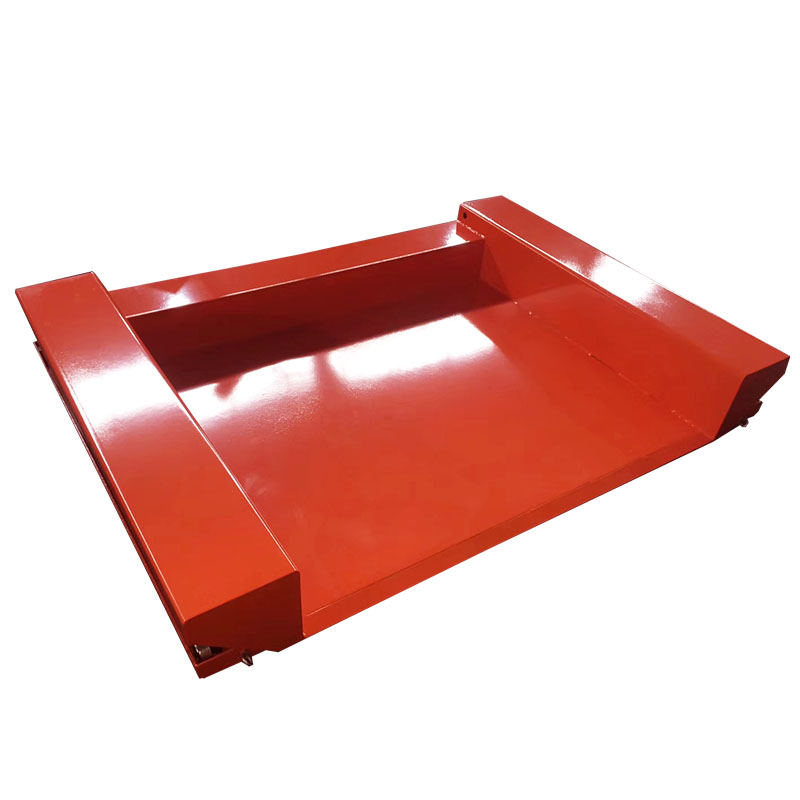

3. Khetha i-roller efanele: I-roller iyisici esiyinhloko sesiteji sokuphakamisa, futhi kuyadingeka ukukhetha uhlobo lwe-roller oluhambisana nezici zempahla kanye nezidingo zokuhamba. Isibonelo, khetha izinto ezingaphezulu, ububanzi besigubhu kanye nesikhala ukuze uqinisekise ukuthi izimpahla zingathuthwa ngokushelela nangokushelela.

4. Cabangela ukunakekela nokugcina: Izinkundla zokuphakamisa amarola ngokwezifiso kudingeka zicabangele ukugcinwa nokugcinwa isikhathi eside. Kudingekile ukukhetha izinto kanye nezakhiwo okulula ukuzihlanza, ukumelana nokugqoka, futhi okuhlala isikhathi eside ukuze kuncishiswe imvamisa yokuphuka nokulungiswa nokuqinisekisa ukusebenza okuzinzile kwesikhathi eside kwesikhulumi.

Idatha Yezobuchwepheshe

| Imodeli | Layisha umthamo | Usayizi wenkundla (L*W) | Ubude beplathifomu obuncane | Ukuphakama kwenkundla | Isisindo |

| 1000kg Umthwalo Wokuthwala Okujwayelekile Ukuphakamisa Isikere | |||||

| I-DXR 1001 | 1000kg | 1300×820mm | 205mm | 1000mm | 160kg |

| I-DXR 1002 | 1000kg | 1600×1000mm | 205mm | 1000mm | 186kg |

| I-DXR 1003 | 1000kg | 1700×850mm | 240mm | 1300 mm | 200kg |

| I-DXR 1004 | 1000kg | 1700×1000mm | 240mm | 1300 mm | 210kg |

| I-DXR 1005 | 1000kg | 2000×850mm | 240mm | 1300 mm | 212kg |

| I-DXR 1006 | 1000kg | 2000×1000mm | 240mm | 1300 mm | 223kg |

| I-DXR 1007 | 1000kg | 1700×1500mm | 240mm | 1300 mm | 365kg |

| I-DXR 1008 | 1000kg | 2000×1700mm | 240mm | 1300 mm | 430kg |

| 2000kg Umthwalo Wokuthwala Okujwayelekile Ukuphakamisa Isikere | |||||

| I-DXR 2001 | 2000kg | 1300×850mm | 230 mm | 1000mm | 235kg |

| I-DXR 2002 | 2000kg | 1600×1000mm | 230 mm | 1050 mm | 268kg |

| I-DXR 2003 | 2000kg | 1700×850mm | 250mm | 1300 mm | 289kg |

| I-DXR 2004 | 2000kg | 1700×1000mm | 250mm | 1300 mm | 300kg |

| I-DXR 2005 | 2000kg | 2000×850mm | 250mm | 1300 mm | 300kg |

| I-DXR 2006 | 2000kg | 2000×1000mm | 250mm | 1300 mm | 315kg |

| I-DXR 2007 | 2000kg | 1700×1500mm | 250mm | 1400mm | 415kg |

| I-DXR 2008 | 2000kg | 2000×1800mm | 250mm | 1400mm | 500kg |

| 4000Kg Umthamo Wokulayisha Okujwayelekile Ukuphakamisa Isikere | |||||

| I-DXR 4001 | 4000kg | 1700×1200mm | 240mm | 1050 mm | 375kg |

| I-DXR 4002 | 4000kg | 2000×1200mm | 240mm | 1050 mm | 405kg |

| I-DXR 4003 | 4000kg | 2000×1000mm | 300mm | 1400mm | 470kg |

| I-DXR 4004 | 4000kg | 2000×1200mm | 300mm | 1400mm | 490kg |

| I-DXR 4005 | 4000kg | 2200×1000mm | 300mm | 1400mm | 480kg |

| I-DXR 4006 | 4000kg | 2200×1200mm | 300mm | 1400mm | 505kg |

| I-DXR 4007 | 4000kg | 1700×1500mm | 350mm | 1300 mm | 570kg |

| I-DXR 4008 | 4000kg | 2200×1800mm | 350mm | 1300 mm | 655kg |

Ipulatifomu yokuphakamisa ama-roller ithuthukisa kanjani ukusebenza kahle kokukhiqiza?

1. Isenzo sokuphakamisa esisheshayo nesishelelayo: Iplathifomu yokuphakamisa amarola isebenzisa idizayini yemishini yesikere ethuthukisiwe, engafinyelela isenzo sokuphakamisa esisheshayo nesishelelayo. Lokhu kusho ukuthi emgqeni wokukhiqiza, abasebenzi bangakwazi ukuhambisa ngokushesha izimpahla noma izinto kusukela phansi kuye phezulu noma ukusuka phezulu kuye phansi, ngaleyo ndlela banciphise kakhulu isikhathi sokuphatha futhi bathuthukise ukusebenza kahle kokukhiqiza.

2. Uhlelo olusebenzayo lokudlulisa impahla: Iplatifomu yokuphakamisa ama-roller ifakwe ama-roller ajikelezayo, angathutha izimpahla noma izinto ngokushelela. Uma kuqhathaniswa nezindlela zendabuko zokudlulisa, ukuhanjiswa kwamarola kunokusebenza okuphezulu kokudlulisa kanye nokumelana nokungqubuzana okuncane, ngaleyo ndlela kunciphisa ukulahleka kwempahla kanye nokulimala ngesikhathi sokudlulisa.

3. Londoloza izinsiza zabantu: Iplathifomu yokuphakamisa ama-roller ingangena esikhundleni semisebenzi eminingi yokubamba esezingeni eliphezulu mathupha, ngaleyo ndlela yehlise umfutho wokusebenza kwabasebenzi. Lokhu kusho ukuthi abasebenzi bangagxila emsebenzini ontekenteke kakhudlwana noma onenani eliphakeme kakhulu, bathuthukise ukusebenza kahle kokusetshenziswa kwabasebenzi.

4. Yehlisa iziphazamiso zokukhiqiza: Isiteji sokuphakamisa izigubhu samukela umklamo othembeke kakhulu kanye nezinqubo zokukhiqiza ukuze kuqinisekiswe ukusebenza okuzinzile nokuphila isikhathi eside kwemishini. Lokhu kusho ukuthi phakathi nenqubo yokukhiqiza, amathuba okungasebenzi kahle kwemishini ancipha kakhulu, ngaleyo ndlela kuncishiswe inombolo nesikhathi sokuphazamiseka kokukhiqiza futhi kuthuthukiswe ukuqhubeka nokuzinza kokukhiqiza.

5. Ukuzivumelanisa nezimo okuqinile: Isiteji sokuphakamisa isigubhu singenziwa ngokwezifiso ngokuvumelana nezidingo ezahlukene zokukhiqiza kanye nezimo. Isibonelo, ubukhulu beplatifomu, ukuphakama kokuphakamisa kanye nokuhlelwa kwama-roller kungalungiswa ngokuya ngezici ezifana nobukhulu, isisindo kanye nebanga lokudlulisa impahla. Leli zinga eliphakeme lokuzivumelanisa nezimo livumela inkundla yokuphakamisa izigubhu ukuthi ifinyelele ukusebenza kahle okuphezulu ezindaweni ezahlukahlukene zokukhiqiza.